What is 3D printing in architecture?

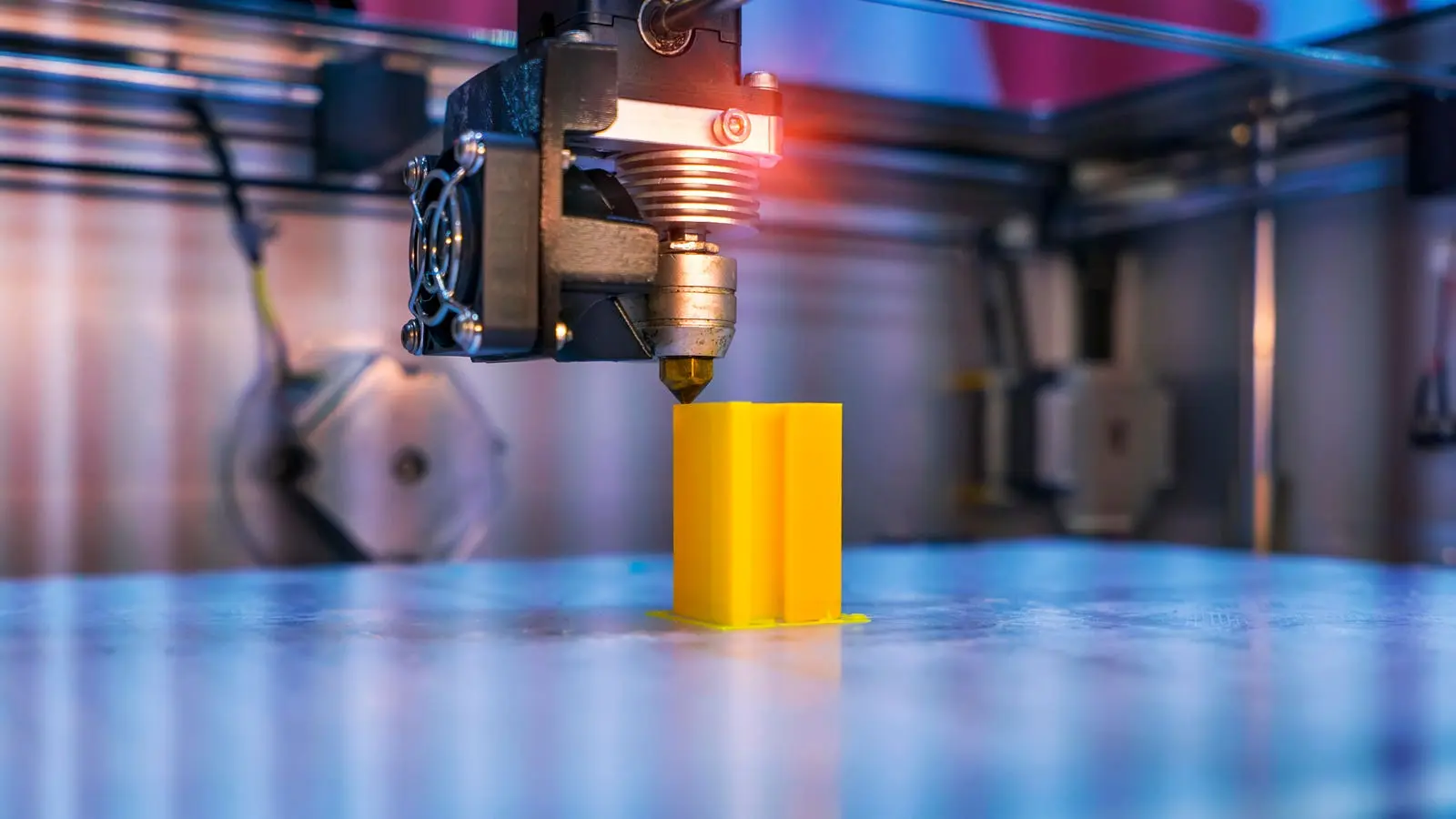

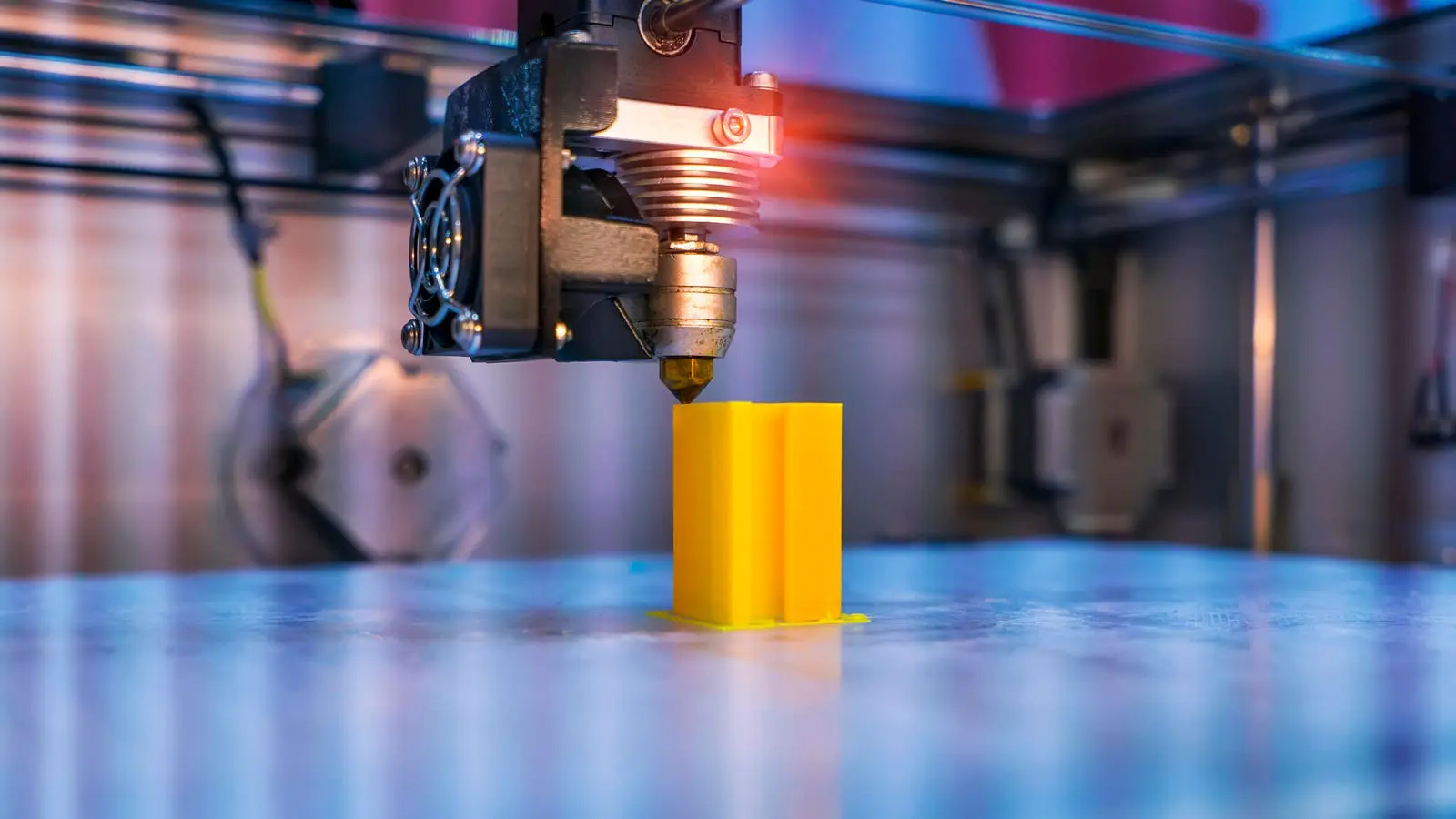

The real-life model of the expected design is understandable through 3D-printing or Three-dimensional printing. It brings the digital model to life by layering all the materials and creating physical models. The models are mostly used to understand and evaluate the design's intricacies and output. It helps builders and construction workers have a real-life reference to the building. It helps give a better understanding to the clients and architectural consultants to perceive a better understanding.

People in the digital era use architect printer modeling across various platforms, including the architectural industry. The models depicting the original building, which we see in various malls, showcase this easily.

In this blog, we will explore how this process can help change the reality of architectural consultants in Dubai.

What is 3D Construction Printing?

3D Construction Printing (also known as Construction 3D Printing or 3DCP) is the process of architectural printing equipment that is equipped with 3-dimensional printing technology that acts as a core method to redevelop buildings or construction components. It serves as a method for manufacturing, constructing elements, or shaping an entire building.

The basic utilization of these 3d printers is to bring concrete polymer metal or any other building material layer-by-layer. [1] [2]

How does 3D Construction Printing work?

Now that we know that 3DCP or 3D Construction printers are those printers used in the construction industry for construction building and relative operations. Let's understand how 3DCP Works and what goes into the process of these printers.

One of the simplest models of 3DCP can be a Device inclusive of a robotic arm that moves back and forth to extrude concrete, for layer-by-layer construction of architectural structures.

Some other models for construction include powder binders and welding equipment.

Powder binding:

Powder binding comprises 3DPrinting using a Basin of Powder, able to solidify the chemical powder layer by layer to bring the digital designs to physical products.

Additive Welding:

Additive welding is printing metal objects through 3d printing. One can see a full-scale demonstration of additive welding as a functional bridge built in Amsterdam, USA. [2]

Types of 3D Printers:

Stereolithography Printers (SLA):

SLA apparatuses harness a laser's precision to solidify liquid resin into intricate, hardened plastic, excelling in crafting objects with meticulous detail and superior surface finishes.

Selective Laser Sintering Printers (SLS):

These printers employ a laser to coalesce powdered material, typically nylon, forming robust components that eschew the necessity for ancillary support structures.

Fused Deposition Modeling Printers (FDM):

Operating through the extrusion of thermoplastic filaments, FDM machines construct durable objects by layering materials, offering versatility in substance choice and functional application.

Digital Light Process Printers (DLP):

Utilizing digital light projection, DLP printers rapidly cure photopolymer resins, a process that results in smoother surfaces and expedites the printing operation compared to SLA.

Multi Jet Fusion Printers (MJF):

In the realm of MJF, printers distribute a fine stratum of powder, selectively applying fusing agents and heat to create items marked by their exquisite detail and dimensional fidelity.

Polyjet Printers:

These printers adeptly jet layers of curable liquid photopolymer, uniquely enabling the fabrication of parts with diverse materials and properties, including varied colors and textures, within a single construct.

Direct Metal Laser Sintering Printers (DMLS):

DMLS devices use a potent laser to fuse metal powder, forging components renowned for their complex geometries and robust mechanical properties, well-suited for intricate metal applications.

Electron Beam Melting Printers (EBM):

EBM technology employs an electron beam as its fusion source, melting metal powder to yield exceptionally dense and strong parts, often finding their application in the demanding sectors of aerospace and medical engineering.

Benefits of 3D Construction Printing

Efficient construction: 3-Dimensional Printing has made the construction process much more efficient and faster, as 3D construction printing can significantly reduce construction time as compared to conventional construction methods.

Lower labor costs: Automation of 3DCPs has reduced the need for manual labor as 3DCPs are efficient enough to tackle most of the intricate operations, Hence reducing the labor costs significantly.

Reduced Raw Material Waste: 3DCP allows Industries to construct using precise measurements and data. This means that the machine will extract and use the material as per the requirement and will use precise material minimizing waste possibilities.

Increased safety: Because of machine automation, the need for manual labor significantly decreases, allowing maximum human safety. With fewer people involved in the construction process, there is a potential for increased safety.

Residential and Commercial Edifices: The realm of building homes and commercial designs for spaces is witnessing a remarkable transformation with 3D construction printing. This method isn't just speeding up the build process; it's reinventing it. We're seeing skyscrapers and cozy homes alike taking shape in record time, with a level of precision and uniformity that traditional methods can't match. It's a game-changer, turning months into weeks and bringing architectural dreams to life faster than ever.

Artistic and Cultural Developments: In the world of architecture, 3D printing is no less than a renaissance. It’s empowering architects to push boundaries, crafting buildings that are as much a piece of art as they are functional structures. From whimsical cultural centers to breathtaking public installations, 3D printing is breathing life into visionary designs that once lived only on paper.

Infrastructure Ingenuity: The impact of 3D printing on infrastructure is profound. Bridges, tunnels, and other public works are not only being built faster but with a flair for design that's unprecedented. This technology is marrying utility with elegance, creating structures that stand the test of time while enhancing the landscape they inhabit.

Sustainable Habitations: In the quest for green building, 3D printing is leading the charge. It’s championing the use of materials that tread lightly on the earth, from rice-based composites to recycled polymers. This approach is carving a path for homes and offices that are not just eco-friendly but are also showcases of sustainable innovation.

Case Studies: Iconic 3D Printed Structures

Tecla House:

A 3D-printed house in Italy, which is one of the first 3D-printed eco-sustainable houses. It was created using a 3D printing technology called Crane WASP.

House Zero:

Another 3D-printed house in Italy was designed by Mario Cucinella Architects. It is a prototype of a sustainable and innovative model for smart living.

3D Printed Two-Story House:

A 3D-printed house in the United States, which is a two-story structure built using 3D printing technology 1.

Milestone Project:

A 3D-printed house in the Netherlands was built as part of a scheme that aims to become the world's first 3D-printed houses used as rental properties.

3D-Printed Concrete Bridge:

The world’s first 3D-printed concrete bridge was completed in the Netherlands. The design life of the bridge is 50 years, and the team notes it saved 40% in terms of construction material, reducing the carbon footprint of the bridge

3D Housing 05:

A prototype home was constructed and exhibited in Milan in 2018, created to demonstrate the potential for new sustainable and affordable housing solutions

Prospective Horizons in 3D Architectural Printing: Concluding Observations

Speculating on future trends, the potential impact on architectural design and consultancy is vast. Anticipate innovations that will redefine construction methodologies, emphasizing sustainability and creativity.

The emergence of 3D construction printing signifies a pivotal shift in the spheres of architecture and construction. This avant-garde technology, fusing the meticulousness and adaptability of 3D printing with the sturdiness of established building practices, is revolutionizing the way we envision, design, and material structures.

Conclusion:

Gazing into the future, the prospects of 3D construction printing are luminous and full of promise. With continuous progress in material science, on-location printing capabilities, mechanization, and synergy withe Building Information Modeling (BIM), the applications of this technology are extensive. Not only will it augment the efficiency and sustainability of construction practices, but it will also unveil novel pathways for architectural ingenuity and innovation.

3D construction printing is not merely a technological advancement; it represents a renaissance in construction methodologies, heralding an era where structures are crafted with heightened precision, efficiency, and a flair for the artistic. As this technology continues to advance, it will have a seminal and transformative impact on shaping the landscapes of the future.